Number of views:

1000

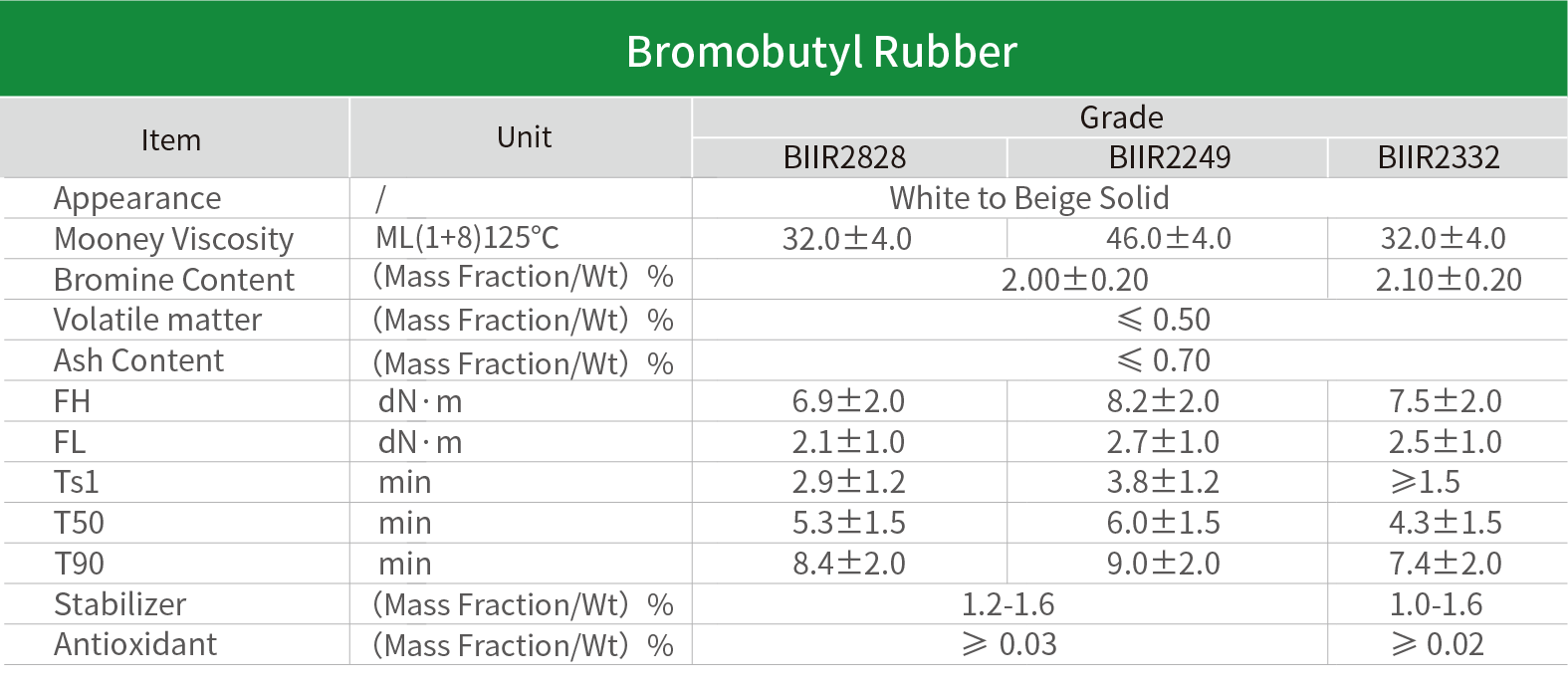

BIIR

Retail price

0.0

元

Market price

0.0

元

Number of views:

1000

Product serial number

Quantity

-

+

Stock:

0

Product description

Parameters

Take the right way

and go far

- Break down the monopoly on foreign markets.

- With excellent airtightness, it is used in tire inner liners and can greatly improve the maintenance rate of tire inflation pressure.

- Its air permeability is 1/7 of natural rubber, and 1/5 of styrene butadiene rubber. The redundant and stable air pressure of the tires ensures long-term driving.

Application

◎ It is mainly used in air tightness of tires to increase the life cycle of radial tires and help the development of eco-friendly tires.

◎ At the same time, (halogenated) butyl rubber is an irreplaceable raw material for pharmaceutical stoppers under the category of antibiotics, which safeguards people’s health.

Scan the QR code to read on your phone

Previous

None

Next

None

1/1

Number of views:

1000

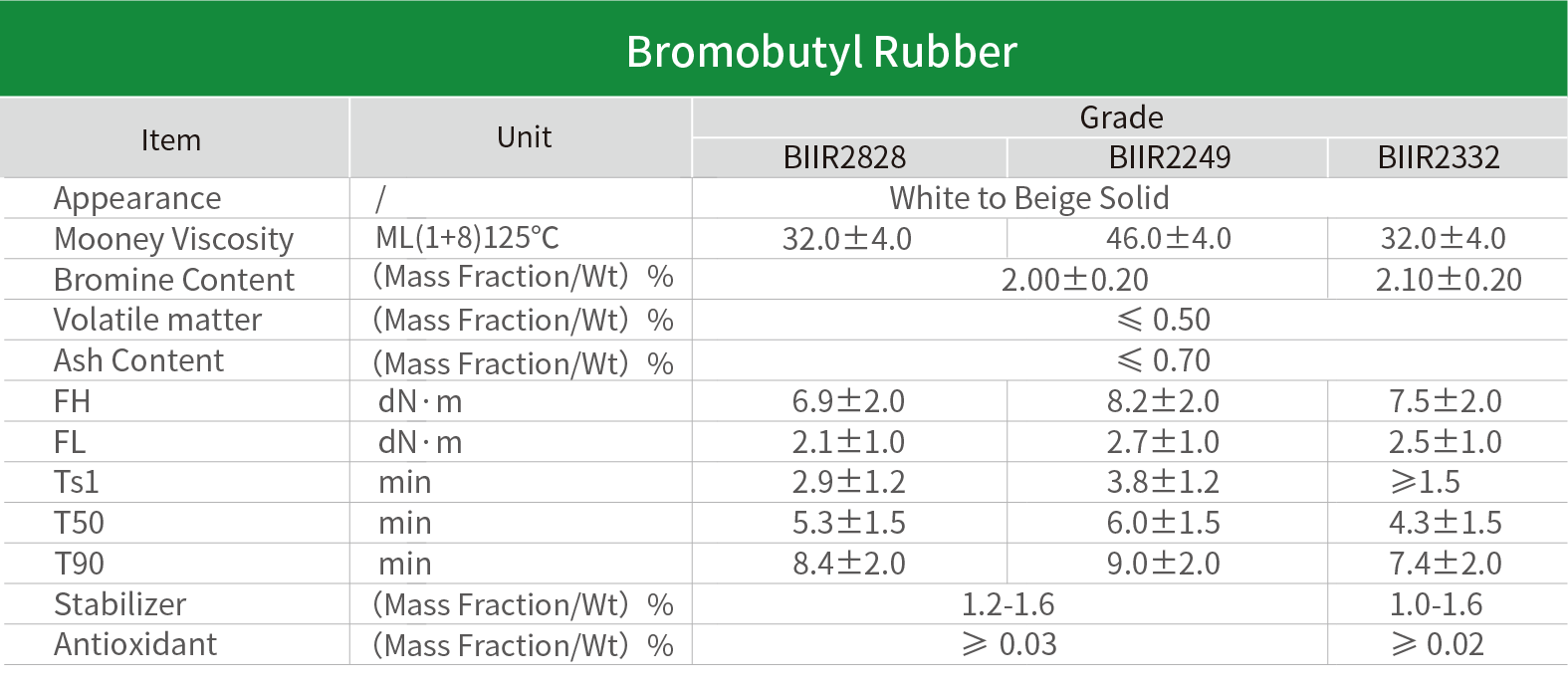

BIIR

Retail price

0.0

元

Market price

0.0

元

Number of views:

1000

Product serial number

Category

BIIR

Quantity

-

+

Stock:

0

1

产品描述

Take the right way

and go far

- Break down the monopoly on foreign markets.

- With excellent airtightness, it is used in tire inner liners and can greatly improve the maintenance rate of tire inflation pressure.

- Its air permeability is 1/7 of natural rubber, and 1/5 of styrene butadiene rubber. The redundant and stable air pressure of the tires ensures long-term driving.

Application

◎ It is mainly used in air tightness of tires to increase the life cycle of radial tires and help the development of eco-friendly tires.

◎ At the same time, (halogenated) butyl rubber is an irreplaceable raw material for pharmaceutical stoppers under the category of antibiotics, which safeguards people’s health.

Scan the QR code to read on your phone

Previous

None

Next

None

SHANDONG CHAMBROAD SINOPOLY NEW MATERIALS CO.,LTD

National Customer Service Line:

Add:

Boxing Economic Development Zone, Binzhou City, Shandong Province

Copyright © 2019 SHANDONG CHAMBROAD SINOPOLY NEW MATERIALS CO.,LTD 鲁ICP备20032804号 Powered by:xinnet